2025-09-22-Digital and Optimal Control-Discrete PID controllers

ELEC-E8101: Digital and Optimal Control-Discrete PID controllers

In the previous lecture. . .

We

- Discussed what happens to the signal when sampling

- Derived what is the sampling frequency so that one can reconstruct the signal

- Evaluated the options of discretization in control systems

- Used discretization methods for designing discrete-time systems

- Used direct methods of designing discrete-time systems

Feedback from last week

- Pace still too fast

→ Should definitely get better today

Learning outcomes

By the end of this lecture, you should be able to

- Design practical PID controllers for applications

- Design anti-windup schemes

PID-controllers

- Proportional-integral-derivative (PID) control is the standard for industrial control

- Over 90 % of industrial control systems use PID control

- The ubiquitous nature of PID control stems from

- Its simple structure

- The distinct effect of each of the three PID terms

- Its established use in industry

- Engineers’ preference to improve existing methods before adopting new ones

- The first theoretical analysis and practical application was in the field of automatic steering systems for ships – early 1920 onward

- Then, used for automatic process control in the manufacturing industry, where it was widely implemented in pneumatic and electronic controllers

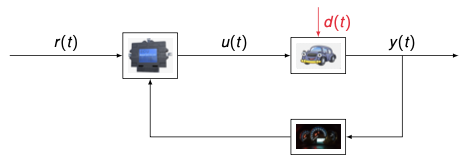

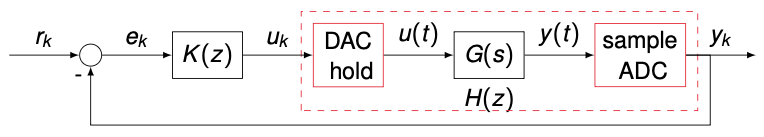

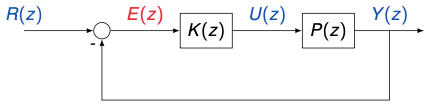

Feedback control in a discrete setting

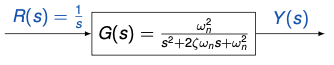

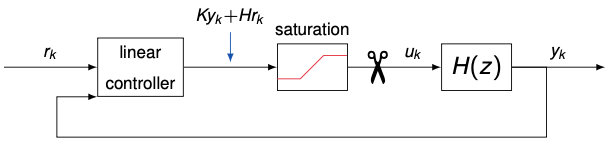

Let us examine the following block diagram of a control system

We have

\[\begin{aligned} Y(z) &= P(z) U(z) \\ U(z) &= K(z) E(z) \\ E(z) &= R(z) - Y(z) \end{aligned}\]Therefore,

\[Y(z) = P(z) K(z) E(z) = P(z) K(z) ( R(z) - Y(z) )\]Solving for $Y(z)$

Closed-loop transfer function from reference/input to output

The block diagram of the control system can be simplified as

- Similarly, for the error $E(z)$

- The problem becomes how to choose an appropriate $K(z)$ such that

- $H(z)$ will yield desired properties

- The resulting error function $e_k$ goes to zero as quickly and smoothly as possible

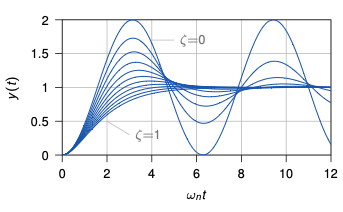

Behavior of continuous 2nd order systems with unit step input

The behavior of the system is fully characterized by

- $\zeta$, the damping factor

- $\omega_n$, the natural frequency

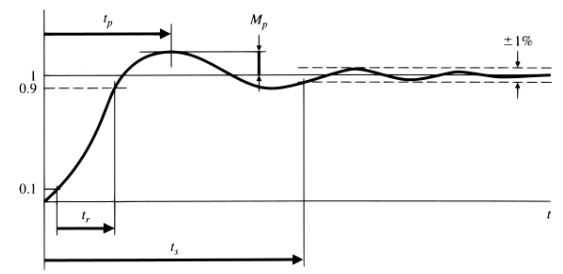

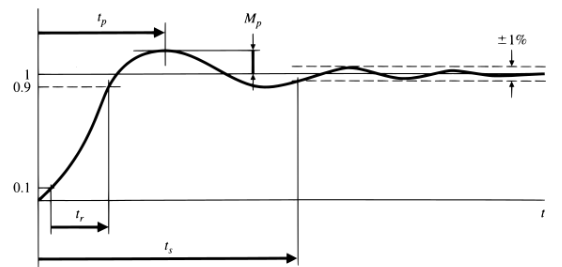

Time domain design specifications

- Typical specifications for the step response (continuous-time) domain

| Specification | Expression |

|---|---|

| Steady-state accuracy | $e_{ss}$ |

| Rise time (10 % – 90 %) | $t_r = \frac{1.8}{\omega_n}$ |

| Peak overshoot | $M_p \approx e^{-\frac{\pi \zeta}{\sqrt{1-\zeta^2}}}$ or $\zeta \geq 0.6 \left( 1 - \frac{M_p \text{ in \%}}{100} \right)$ |

| Settling time (1 %) | $t_s = \frac{4.6}{\zeta \omega_n}$ |

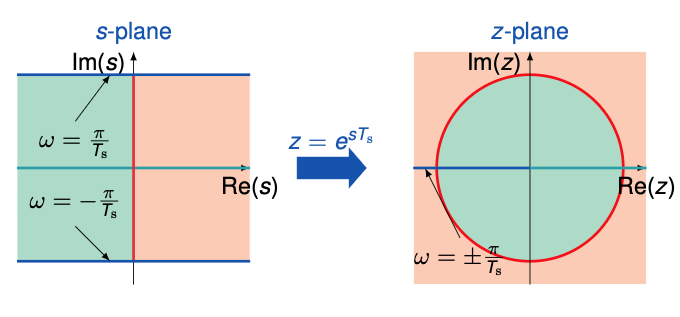

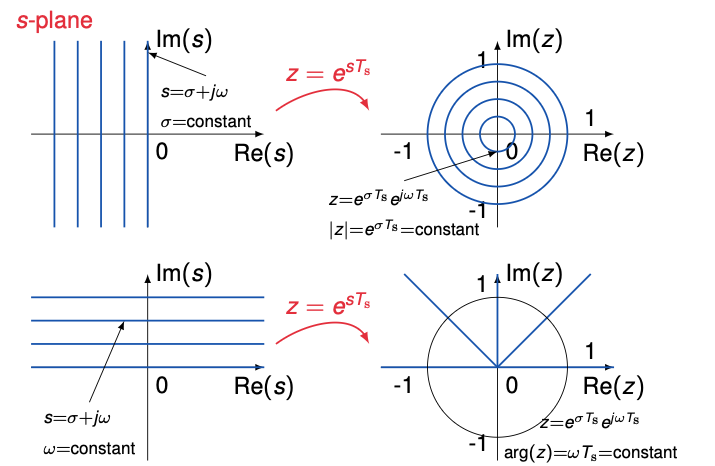

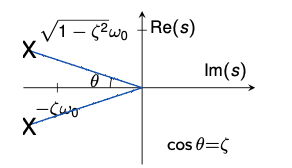

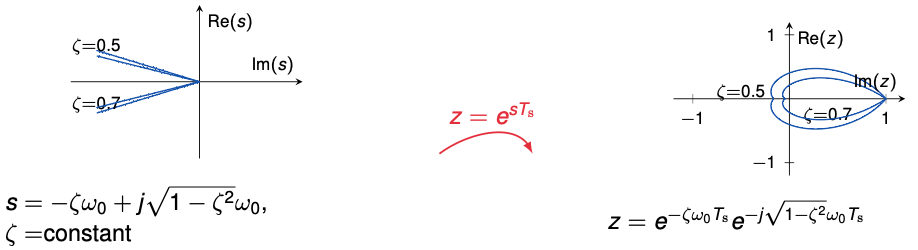

The mapping from the s-plane to the z-plane

Pole locations for constant damping ratio $\zeta < 1$

\(s^2 + \zeta \omega_0 s + \omega_0^2 = 0\) \(\implies s = -\zeta \pm j \sqrt{1 - \zeta^2} \omega_0\)

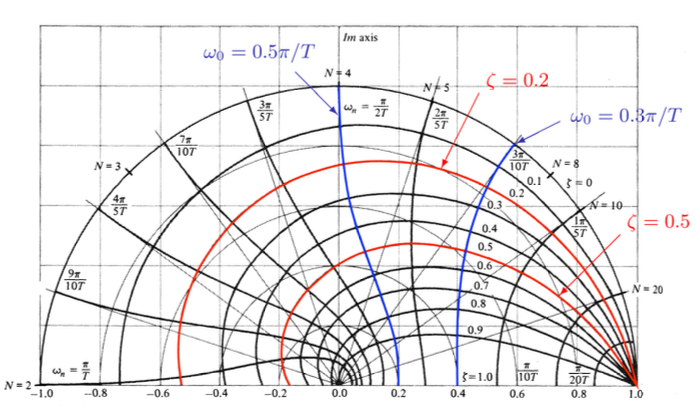

$z = \text{plane loci of roots of constant } \zeta \text{ and } \omega_n$

$s = -\zeta \omega_n \pm j \omega_n \sqrt{1-\zeta^2}$

$z = e^{Ts}$

$T = \text{sampling period}$

Time domain design specifications

- Typical specifications for the step response (discrete-time domain)

Steady-state accuracy

\(e_{ss} = \lim_{z \to 1}(z - 1) E(z)\)

Rise time (10% – 90%)

\(t_r = \frac{1.8}{\omega_n}\)

Peak overshoot

\(M_{\mathrm{p}}\approx e^{-\frac{\pi\zeta}{\sqrt{1-\zeta^{2}}}}\mathrm{or}\zeta\geq0.6\left(1-\frac{M_{\mathrm{p}}\mathrm{in}\%}{100}\right)\)

Settling time (1%)

radius of poles:

\(|z| < 0.01^{\frac{t_s}{t_s}}\)

Example – the car from the last lecture

- We take the transfer function obtained with the Tustin method and set $m = 1 \, t$, $T_s = 10 \, \mathrm{ms}$, and $\beta = 0.01 \, 1/s$:

- Assume the system is controlled by

- Find the steady-state error to a unit step $e_{ss}$

- Is the step response settling time $t_s < 1$?

Example – steady-state error

- We already showed that

\(E(z) = \frac{1}{1 + H(z)K(z)} R(z)\) - Where the input is

\(R(z) = \frac{z}{z - 1}\) - And the controller

\(K(z) = K_p = 10\) - How do we find the steady-state error?

- What happens for eₖ in the limit?

→ We can very precisely track the step input!

Example — settling time

- For the settling time, we said

\(|z| < 0.01^{\frac{T_s}{t_s}}\)

→ We first need to find the poles of the closed loop system!

\[H_\text{cl}(z) = \frac{H(z)K(z)}{1 + H(z)K(z)} = \frac{10 \frac{z+1}{200.01z - 199.99}}{1 + 10 \frac{z+1}{200.01z - 199.99}} = \frac{10(z+1)}{200.01z - 199.99 + 10(z+1)} = \frac{10(z+1)}{210.01z - 189.99}\]- Poles are the zeros of the denominator:

→ Then, we check the settling time:

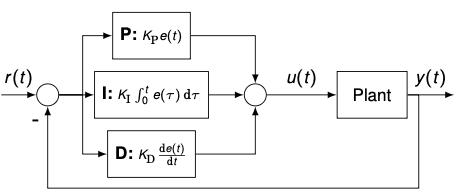

\[0.9 < 0.01^{\frac{0.01}{1}} \implies 0.9 < 0.95 \quad \checkmark\]Continuous-time PID-controllers

- P: amplifies the error by $K_P$

- I: eliminates the residual error by integrating over its historic cumulative value

- D: looks ahead by exerting control based on the rate of change

- The continuous-time PID-controller in the time domain is

- And in the Laplace domain:

\(U(s) = \left( K_P + \frac{K_I}{s} + K_D s \right) E(s)\)

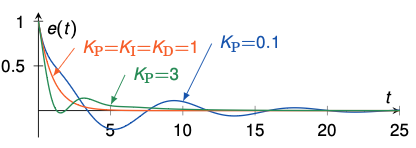

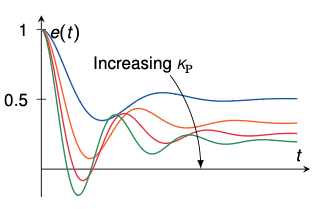

P-controller

- The “obvious” method – proportional control

Example: transfer function $G(s) = \frac{1}{s^2 + s + 1}$ with step input

- Higher $K_P$ brings the error $e(t)$ closer to zero but never reaches it

- Also, the overshoot increases

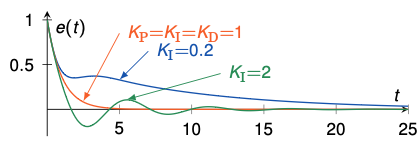

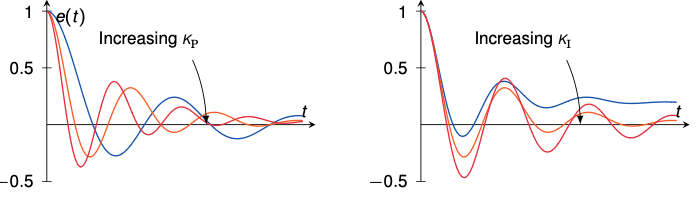

I-controller

- An integral term increases the action depending on the value of the error and how long it has persisted

- If control action is too small and a steady-state offset remains, the action will increase

- A pure integral controller could bring the error to zero, however

- It would react slowly in the beginning

- Once the error is zero, the integral is still non-zero and causes overshoot and oscillations

- Alternative: PI-control, often used for example in motor control

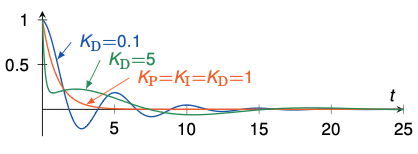

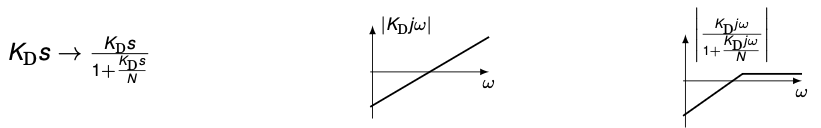

D-controller

- React to changes in the error

→ If error starts to shrink, can decrease control action, otherwise increase - Aims at flattening error trajectory

- Ideal derivative control cannot (and must not) be realized in a PID-controller

- Practical systems always contain high frequency disturbances, which are amplified by derivative control

- Because of that, a low-pass filter/lag term is usually added

\(K_D s \rightarrow \frac{K_D s}{1 + \frac{K_D s}{N}}\)

- Other practical modification: take derivative only of the output, not the reference and error signal

PID-controller

From continuous- to discrete-time PID-controllers

- Simple discretization

- Therefore

- Taking the z-transform:

- Note: there are other interpretations of discrete-time PID-controllers

- For example, if backward integration is used in the integral part:

- The discretization of a practical PID-controller is as straightforward

Tuning PID-controllers

- The structure of the used discrete PID algorithm must always be told together with the tuning parameters $K_P$, $K_I$, $K_D$ (and $T_s$)

- Controller design is typically based on heuristic design methods for selecting the controller parameters

- The principal design goal is stability: the system is stable when the closed-loop poles are on the left half of the $s$-plane or inside the unit circle in the $z$-plane

- Secondary criteria are, for example, rise time, overshoot, settling time, and steady-state error

- These can be analyzed graphically from impulse, step, and ramp responses of the closed-loop system

Table: Effect of increasing a parameter independently

| Parameter | Rise time | Overshoot | Settling time | Steady-state error | Stability |

|---|---|---|---|---|---|

| $K_P$ | Decrease | Increase | Small change | Decrease | Degrade |

| $K_I$ | Decrease | Increase | Increase | Eliminate | Degrade |

| $K_D$ | Minor change | Decrease | Decrease | No effect in theory | Improve if small |

Empirical tuning rules

- Start with $K_P = K_I = K_D = 0$

- Increase $K_P$ until you reach the reference value fast with some overshoot and oscillations

- Increase $K_D$ until the oscillations decrease to a satisfactory level

- Increase $K_I$ so that steady-state error will be eliminated

Tuning rules for PID controllers

J. G. Ziegler and N. B. Nichols. “Optimum settings for automatic controllers”. In: Transactions of the American Society of Mechanical Engineers 64.8 (1942), pp. 759–765

Actuator saturation

- Most control systems are designed based on linear theory

- A linear controller is simple to implement and performance is good, as long as dynamics remain close to linear

- In practice, we always have nonlinear effects, e.g., actuator saturation, that we need to take care of

- Saturation, if ignored in the design phase, can lead to closed-loop instability, especially if the open-loop process is unstable

- Main reason: the control loop gets broken if saturation is not taken into account by the controller

Saturation function

- Saturation can be defined as the static nonlinearity

- $u_{\min}$ and $u_{\max}$ are the minimum and maximum allowed actuation signals

- Example: for a typical DC motor, we have $u_{\min} = -12\,\text{V}, \, u_{\max} = 12\,\text{V}$

- If $u$ is a vector of $m$ components, the saturation function is defined as the saturation of all its components

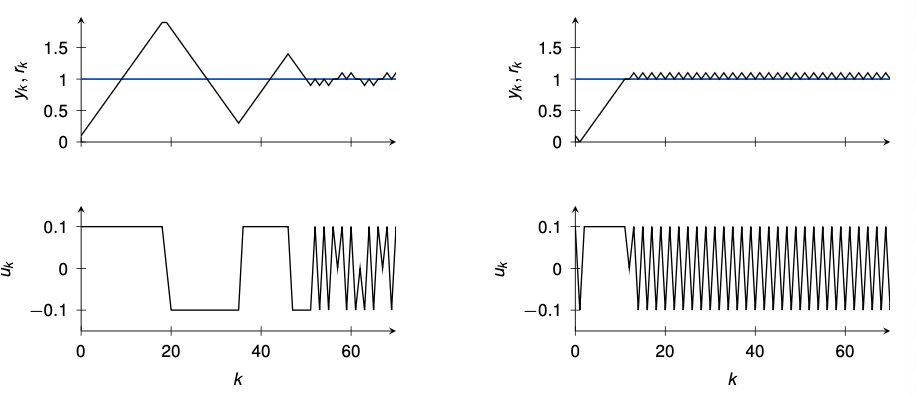

The wind-up problem

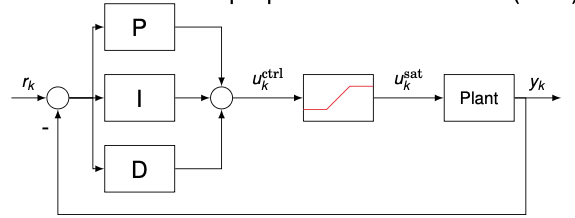

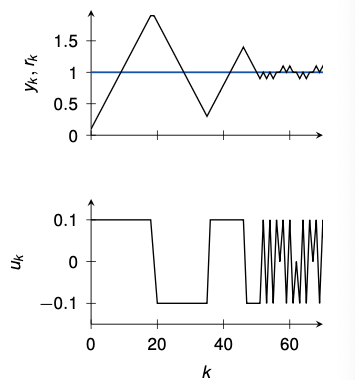

Consider a simple process with saturation (±0.1) and PID gains $K_P = K_I = K_D = 1$

- Slow convergence to steady-state

- The reason is the “wind-up” of the integrator contained in the PID-controller

- The integrator keeps integrating the tracking error even when the input is saturated

- Anti wind-up schemes avoid this effect

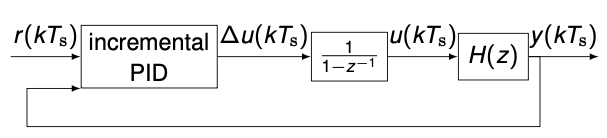

Anti-windup #1: incremental algorithm

- It only applies to PID control laws implemented in incremental form

where

\[\Delta u(kT_s) = u(kT_s) - u((k-1)T_s)\]- Stop integration if adding a new $\Delta u(kT_s)$ causes a violation of the saturation bound

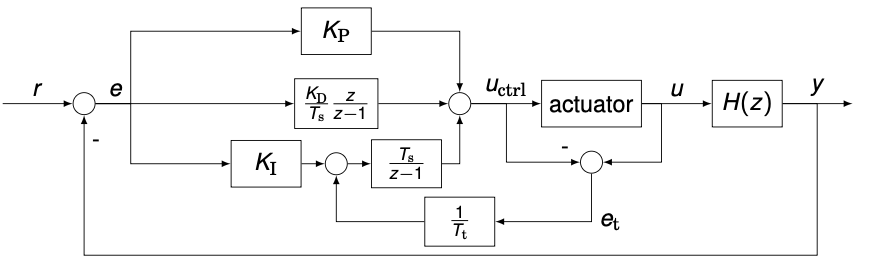

Anti-windup #2: back-calculation

- Anti wind-up scheme has no effect when the actuator is not saturating ( $e_t = 0$ )

- Time constant $T_t$ determines how quickly the integrator of the PID-controller is reset

- If the actual input $u$ of the actuator is not measurable, we can use a mathematical model of it, e.g., $e_t = u_{ctrl} - \text{sat}(u)$

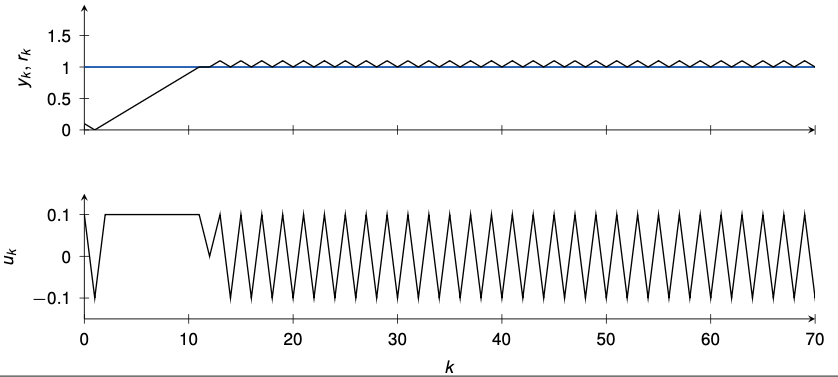

Anti-windup #2: example

- Let’s consider again the PID-controller from before ($K_P = K_I = K_D = 1$) and add back-calculation with $T_t = 1$

- Windup is avoided due to back-calculation

- Note: only one tuning parameter ($T_t$), but only applicable to PID-controllers

Benefits of the anti-windup scheme

- In case of windup we have

- Large output oscillations

- Longer time to reach steady-state

- Peaks of control signal

Hardware demo

Practical demonstration of PID-control: https://youtu.be/fusr9eTceEo

Learning outcomes

By the end of this lecture, you should be able to

- Design practical PID controllers for applications

- Design anti-windup schemes